object lesson: movement in textiles

At the last V2_ E-Textile Workspace there was a lot of discussion about using movement in textiles. Previously, we'd done some ad hoc experimentation with Flexinol shape memory alloy in the V2_ Workspace, but we all agreed it would be interesting to see what we'd come up with independently.

muscle wire vs motors

My own experiments with shape memory alloy/muscle wire last year had been disappointing. I had tossed everything in a bag and gone on with another project. Perhaps this time I can make a bit more progress.

The big problem with my previous experiments with movement in textiles was the strength of the shape memory alloy. The sample structure I made was not able to be moved with the muscle wire I had.

I decided to try using small motors for these experiments. Mostly because they can (hopefully) exert enough force to make the movement I hope to achieve. Secretly I also want to use them because I have a deep love of low-tech.

I have some small pager motors and micro motors of varying strength. After a few more experiments with these, it became apparent that these were not going to achieve the forceful movements I expected. I will need to get tricky.

study 1: deployable structures

In her Fairytale Fashion project, Diana Eng examines the application of deployable structures in textile and clothing. This seemed to me a possible solution to the problem of motor (or muscle wire) strength. If the movement is more inherint to the structure, it should "want to move" when a weak force is applied to it.

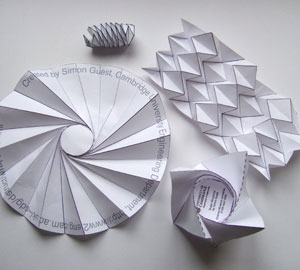

I made a few paper examples from patterns I found online. The large circular one on the left of the photo below is my favourite. The pattern is from Department of Engineering, University of Cambridge and I highly recommend making one! It contracts into a cylinder form, rotating the small central circle as it does so.

I tried transfering the concept to fabric and here are my results.

paper models

paper models fabric application of the circle

fabric application of the circle

With the right materials, this could be a nice decorative element on clothing. Much more interesting to me, however, would be making something like this into a gusset. When placed at a body joint, for example at the elbow, the body's own movement could be used to expand and contract the structure.

study 2: small movements within a larger landscape

Next I started thinking about using the motor for more simple rotating movements and how that could be applied within a larger textile landscape to create interest and playfulness. I'm not entirely convinced of the practical applications of moving textiles with motors, so this explores a purely decorative use.

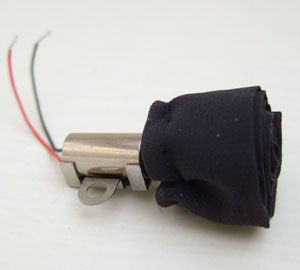

motor with fabric coil

motor with fabric coil fabric coils stitched into larger structure

fabric coils stitched into larger structure the two centre coils are motorized

the two centre coils are motorized

Unfortunately the motors are stopped by relatively small resistance, so whenever the fabric coils catch on anything, they stall. Also, the noise they make is quite... motorey...

study 3: bead motor

Since the fabric coils were catching on almost anything they touched, so I decided to try using something smooth instead. Beads can be attached to the motor axis and rotated within a fabric casing.

One practical use for movement in textiles is to display information - maybe this could be a nice alternative to LEDs...

a motorized bead

a motorized bead half of the bead is painted

half of the bead is painted the finished casing

the finished casing

The video shows the rotation stopping and starting. Currently there is no control over which side of the bead faces up when rotation stops. Next steps are to work on this, and perhaps play around with colour-blending and animation.